To demonstrate how tricky it can be for shop floor workers to select the right tool, Gerrit Kremer pulls out a box containing six near-identical inserts from Seco Tools’ Turbo 16 family.

“It’s quite hard to identify which tool is which when you have them lying around on your table, and that’s where we started seeing the potential for creating customer value,” says Kremer, Seco’s Global Product Manager for Digital Product Service.

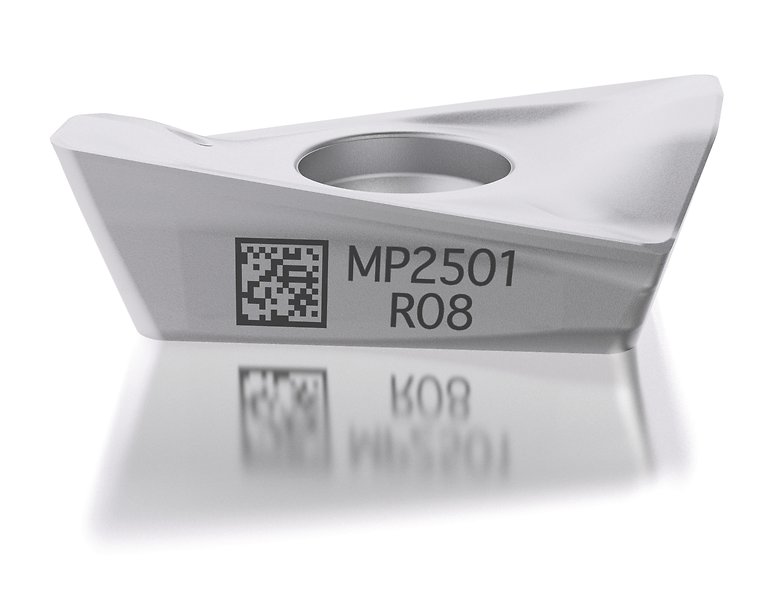

New data matrix identification codes

The Turbo 16 family is the first range of Seco Tools inserts to be laser marked with the new data matrix identification codes that the company launched in September 2021.

Data matrix symbols look like small QR codes, with black and white cells arranged in a square or rectangular pattern. They can encode a 50-digit number in a symbol that is reliably readable down to 4mm2 in size.

Shop floor workers now simply need to scan the code with the Seco Assistant app to identify which Turbo 16 insert they are holding.